Construction Management encountered a bit of an educational boom in recent years with everyone from four-year universities to local community colleges filling the airwaves with advertisements for the new “High tech, fast-paced” world of construction management.

While it’s certainly true that some companies make an effort to stay on top of technology the reality is that the vast majority in the construction industry do not hold a degree. The “school of hard knocks” remains the primary educator for the rank and file. Not that I’m picking on them. The construction industry is somewhat anachronistic in that it’s still fairly common for a person to start as a laborer and work their way up to leadership. People who’ve earned their status tend to respect what’s learned through hands-on experience. There’s a natural urge to keep what works, so in some ways innovation is slow.

Modern Dinosaurs

Technology firms focused on the construction industry have a split in their demographics. The bulk of the existing leadership is composed of elderly professionals who appreciate operational familiarity with legacy programs. The small remainders are typically younger professionals looking for an edge in the market. Lacking a long history with existing programs, these folks are open to learning to use whatever software they’ll need.

We all know how to use a road.

Take a moment and consider how homogenized the computer experience has become over the last twenty years. Everything from websites to spreadsheets will jump to the next value if you press “Tab”. Left mouse clicks select, double left mouse clicks open in just about every application. Navigating unfamiliar programs is MUCH less frustrating because we don’t have to think about these little details.

Except in this industry.

Inexplicably, popular estimating programs will not tab to the next obvious insertion point. Spell-check and formatting options are bafflingly missing in Project Management software that generates RFI’s, Memos, Change Orders, and Payment applications that get submitted to clients and architects. Copying a file may result in a pop-up window telling you it’s done without opening the copy or the original. Often otherwise identical insertion windows will wait until you’ve entered considerable data before a pop-up window informs you everything was deleted because no job was selected.

It’s common for programs to have incredibly counter-intuitive command names and sub-options. This is likely due to proprietary naming conventions. But I believe there’s another, much more frustrating reason.

Programs for the construction industry are written by and for people who have never used a program that was streamlined for the construction management user.

“You know who you are”

Over time, the firms making these programs have added features here and there which are trumpeted in advertisements as improvements. The obsession with legacy layout has resulted in programs that are very frustrating to use. For example, one very popular project management program has job reports separated under upwards of five different sub-headings. It’s not possible to go to “reports” and find everything you’d need. Instead you’re forced to navigate through menu’s primarily used for data entry.

Dumb defaults

Above and beyond these arbitrary obstacles, the programs “default logic” is genuinely irritating. Getting a report to print often requires as many as twenty different operations to select dates, printer settings, and so forth. 99.999% of the time you just want it print the current report from the start of the job to today! Somehow it’s never an option to “save” all those keystrokes into a single operation.

Users are not permitted to alter menu structure or interface to improve workflow. I was at a training seminar for the most popular electrical estimating program in my area when I asked the instructor why the program wouldn’t allow me to tab to the next insertion point and partially type the variable I wanted to search for.

The instructor appeared genuinely shocked that anyone would want a $3,000 program to be quick to use. “I guess there are some things that could be a little better” was the instructors reply. Antiquated input structure slows the users down at the worst possible time. This program goes back nearly 20 years and boy, you can tell!

Quantity Take Off systems

Estimating software’s are often referred to as Quantity Take Off (QTO) programs. Older systems utilized a digitizer for data entry whereas most of the newer systems import plan files and digitize the measurements on the computer screen. Digitizing, is correlating the represented image to a scaled value linked in to your QTO and potentially your pricing system. Rather than fussing around with scales, calculators and graph paper, you can lay down a linear takeoff on the computer screen. The program will automatically calculate the real length, and link that measurement to a takeoff value such as “base molding”. Most QTO systems operate entirely on-screen allowing the plans and the takeoffs to be visible at the same time. These systems don’t require plan printing AT ALL which is not only less wasteful, but it’s also MUCH faster because you’re not constantly waiting on a plotter or print shop to deliver.

It’s worth taking a moment to discuss old-school digitizers. Generally they were a large fixture or mat placed on a plan table onto which the drawings were physically secured. Using a stylus or digitizing mouse, the plans were traced with the measurements being correlated by scale and input designation. Digitizers were particularly useful for earth-work take offs where the existing and proposed elevation contours could be traced as separate layered conditions that were interpolated into a wire frame model depicting the site cuts, fills, paving, foundations, and so forth.

In use they were cumbersome because if the page moved, the entire plan had to be benchmarked again. The estimator had to mark the plans wherever a measurement had been taken to ensure it wasn’t doubled up. The data entry was difficult for frequently interrupted measurements because the digitizer is huge, and there was rarely a convenient place for the monitor, keyboard, and mouse near the plans. If there was an addendum that replaced a sheet of your takeoff, it was nearly impossible to successfully edit all the affected layers of a takeoff. Ergonomically, these systems resulted in some very long days for the estimator.

Some of the older systems were a bit odd to say the least…

Going to the big screen

Today most QTO programs that will import a plan file and allow takeoffs using the computer’s monitor, mouse, and keyboard. Some proprietary systems utilize a touch-screen tablet as well. I would heartily recommend the computer based systems over the traditional digitizer or the hoary old manual measurement methods.

There are a few things to consider. First off, plans are more or less standardized according to Architectural paper sizes. The two most common are D and E1. “Arch D” measures 24″ x 36″ (610mm x 914mm) and “Arch E1″ measures 30″ x 42″ (762mm x 1067mm).

Arch D is the more common of the two for general construction, however large buildings or those drawn by Architects with especially quirky eyeglasses go with Arch E1.

Arch D is 6 square feet, and Arch E1 is 8.5 square feet per page. Most reasonably sized monitors will display 2-3 square feet maximum. A goodly portion of which is consumed by the program that actually does the measurements. This means that a plan displayed at full size in a software window will reveal less than 30% off the total surface area of the plan. The most common scale is 1/8″per foot which means a 6″ wall is depicted at 1/16” thick at full size (100% zoom).

Ramp the zoom

In order to get anything done, you’ll have to get used to one of the most frustrating aspects of software oversight I’ve ever seen. The plan area is huge relative to the window through which you’re working. This means that the plans are either zoomed-in such that you can’t see areas immediately adjacent to what you’re looking at, or you’re zoomed-out such that you can’t see any detail. I call it “ramping the zoom” because you’re zooming in to start a measurement, then zooming out so you can cross the plan area faster, then zooming back in for the “landing”. I know of one program that offers a “magnify” hot-key that pops up a magnified window at your cursor when it’s pressed but leaves the page zoom level alone.

Key notes are often listed on plan margins, in a small font, in ALL-CAPS, in huge blocks of text that may not actually list left to right, top to bottom. It’s a gigantic pain in the rear to go define a key-note and return to what you were doing because it’s invariably across the sheet, and never where you’d expect it to be. Few if any systems have a “go back” function allowing you to return to the display settings and area of your last measurement.

Traversing the plans

Since the plan area is so large relative to the displayed area, it’s a constant necessity to scroll vertically and horizontally. Some programs default to “right-click = grab” which means you click (and hold) to “grab” the page which then moves with your mouse. Other programs use the mouse roller in combination with Shift or Control to scroll horizontally or vertically. It can take a lot of “getting used to” learning how to smoothly navigate the page. The “grab” is less difficult to operate but some mice have “smooth-rolling” scroll wheels that you can spin quickly to smoothly cross the page.

Most systems employ an “overview window” which shows a very small image of the plan with a boxed shadow depicting the viewing window’s boundary relative to the sheet. You can grab the box and move what’s displayed in the viewing window without changing the zoom setting. This tends to be very coarse and difficult to employ making them pretty useless.

Every system I’ve used had selectable cursors with defined functions. A “grab” is different from a “takeoff tool”, which is different from a “zoom” tool. These are generally located on toolbars at the margins of the working window. One of the market leaders inexplicably doesn’t allow keyboard shortcuts to switch to all of the cursor functions. This means you’re forced to mouse all the way to the top of the page to get to toggle between functions you CONSTANTLY change. It’s a huge waste of time. These programs already require the keyboard to operate some functions, oh how I wish they would allow users to set up hot keys!

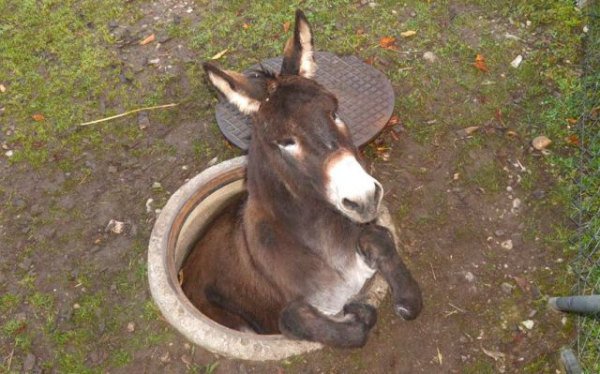

Submitted without comment

So what do you do?

One costly option is a large monitor. Larger monitors can display more working area of the plan for any given level of zoom. Time spent ramping the zoom just to continue a measurement is greatly reduced. Bear in mind that larger monitors really benefit from a good video card. “Big but blurry”, isn’t helpful. It’s worth mentioning that system requirements for these programs aren’t very stringent but minimum level systems will slow down towards the end of a particularly complex and lengthy takeoff. Losing your productivity at the last hour is extremely stressful.

Everyone’s going to have their preferences but I’ve found that a great deal of QTO program setbacks can at least be mitigated by using a track ball mouse. I can whip the cursor across the screen with one motion rather than being forced to wipe the mouse across a pad several times. The sensitivity settings on mice will always be a frustrating compromise with QTO systems because you’ll really need precision control and rapid movement. The trackball accomplishes this pretty well. Every QTO program I’ve used required some degree of numerical data entry on lots of individual takeoffs. The cursor stay’s put while you move back and forth to the numeric keypad. If you do use a standard mouse, I recommend you buy a premium quality one. A mouse that would work fine for most applications will force you to pick between speed and accuracy. A job with miles of measurements will take its toll on you in short order.

If there are any hardware developers out there, I have a suggestion for you. Take the “3D mice” that architects and engineers use for 3D CAD/ CAM programs and re-program them to be used as analog joystick mice. The multi-axis control could be used to control several functions simultaneously on QTO programs. Being able to zoom out, while traversing the sheet with an ongoing take-off measurement would allow “cross the building” measurements like main trunk lines without all the tedium or repetitive stress injuries.

Menu madness

Another aspect of QTO programs is a preoccupation with staggeringly long menus of parts, assemblies, or whatever the programmer named them. For example an interior wall in a commercial building might have 3-5/8″ metal studs 10′ tall 16″ on center, with 1/2″ gypsum wall board on both sides finished to level 3.

It makes sense that this is just one option among literally thousands of possible configurations. Most plans will include a wall type schedule listing only those that are used on the job. For the sake of example, let’s say there’s five shown.

QTO programs tend to be built around menus that list every possible option for a given assembly type. That means that an estimator in this example would only use five out of maybe 2,000 options which are all presented in a truncated form alongside one another. Typically this list is buried in a sub-folder, within a directory, and so forth. Everything is a list of lists!

It would be substantially less difficult to set up the program to ask sorting questions of the estimator to present a shortened list of available options. Allowing the estimator to define and name the five options so they match the plans and allow for quicker repeated access would cut the time spent scrolling through 2,000 item lists. In the same way that a traveler packs clothes appropriate to their destination, so too should the estimator be allowed to make a shorter list of parts they intend to use for each job. Some programs can import styles or preset lists to help with this. It’s worth taking the time to cull the list to what works for you. Still it’s a shame that the “default” is so dim-witted.

“No sir, she’s not built for speed…”

One easily overlooked aspect of QTO systems is information management. Plans come into the program in any one of dozens of file formats. Most programs must convert the plan files to TIFF format to work. The original file, and the new TIFF files must be stored somewhere. Some programs will allocate memory space on the system/network for these files, others will allow the user to select each one individually. Be careful because it’s very common for companies to track projects in Estimating in different file locations from projects in Project Management. Moving files from one folder to another may prevent the QTO program from working and copying them to both locations consumes too much space.

QTO programs that are tied to pricing programs often must import/export between the programs. Job numbers, file locations, dates, times, and job names must be identical to work. It’s therefore impressive how rarely the defaults are set to prevent errors!

Estimating systems

Estimating or pricing programs are much older than QTO systems. Most estimating programs feature some means of importing current material pricing. Ranging from general to trade level specialization, these systems can provide a benchmark for labor productivity and commodity level material pricing. Specialized items are priced via the distributor chain. Being older, estimating programs are very prone to “legacy layouts” that often look and feel like something out of the 1990’s. Some popular project management programs include an estimating function. Project Management programs are a specialization of accounting software. As a result it’s built to automatically save anything that’s entered. Anything you change is changed immediately and forever. “Undo” is still being touted as a “new innovation”! If you want to conduct a “what-if” scenario with an estimating program, you’d better be sure of what you’re doing. Often it’s easier to just copy the job and futz with the copy so the “original” is still there for you to return to.

Updated pricing

“Automatic daily updates of all your commodity pricing” sounds great but there are many defaults that work against this notion. For example, it makes sense that once your deadline has passed, your price should remain “frozen”, i.e. not continually updating. When you create a new job, there will be some means of identifying the bid deadline. On many systems this will default to the current date and time. That means the pricing is frozen at the start.

The deadline spiral

You might have a quick bid that you put together in an hour. No big deal that the pricing is frozen right? WRONG! Some “automatic” updates will automatically connect to a server, download all the current pricing, then WAIT TO UPDATE until a job is created that’s not frozen. That means that as long as you’re doing quick-hitter bids, none of the system material pricing will update!

But wait, there’s more! Let’s say you create a new job in a hurry and forget to enter the deadline that’s a week away. If you go back and edit that setting you’d think you are in the clear. NOPE! Often in a sub-menu option there will be a check box for “freeze pricing after deadline”. If you create a job with frozen pricing, it stays frozen until you uncheck that box AND set the bid date for the future.

“So surely it’ll update now?…Right?!?”

Sadly, no. Once a job has been “frozen” its ignored by the updating function. You’ll now have to work your way through the intricate menus regarding imported material pricing and specifically force the program to update the job you just created. Now, finally the estimate will use the updated material pricing. Just don’t forget to re-check the “freeze pricing after deadline” box! This entire spiral of madness exists for two reasons. First, the program doesn’t default to updating material pricing for every new job. Second, the “freeze pricing after deadline” check box is needlessly pedantic. It’s understood that pricing freezes after the deadline, so it’s counter-intuitive that changing the deadline fails to trigger the update. A pop-up screen warning of an impending update following a deadline edit would prevent any mistakes.

If an old job needs updated material pricing, it’s better to make a copy of the job set to the current date.

However your specific system works, you must verify that your jobs are working off the most current information. Some programs allow a user to search the material database. Pick something commonly used in your estimates and compare the database to what your job is listing. I’ve found that out-of-date material pricing can “stack up”, pushing your bid way off the mark.

Be advised that updates can be wrong. I’ve received “Emergency notification” from these services advising estimators that a mistake was discovered. I’ve also caught material pricing that was set to the wrong $/ unit magnitude. For example a part might be priced per each (E), per ten (D), per hundred (C), or per thousand (M). Most systems include a drop down list with E, D, C, and M. Updates can change the cost per unit magnitude. Imagine being wrong by three orders of magnitude! That’s a very serious problem I’ve encountered more than once.

“The stress eventually drove Rusty here to a life of crime.”

Patchwork leads to more work,- for you

Automation is often touted as an error-reducing technology. Programs that must import and export with one another are often “patched” via a set of concealed default conditions. In practice this means that anything the patch programmer interpreted differently than you do, will generate an unpredictable result.

Because estimating programs have the historical foothold on the market, “patched” QTO systems are generally hobbled to suit the estimating program’s limitations. A QTO system might be able to let the user modify far more parameters of a given “part” you’d use for a takeoff than the estimating system can support. The “patched’ duo is sold with those parameters helpfully disabled. Advances in QTO programs are often held back by antiquated estimating software. It’s not really possible to easily link independent programs without substantial programming capability. However most QTO and estimating systems will import/ export spreadsheet files. It may take some work, but it’s generally possible to get the two programs working by spreadsheet exchange.

New part = no part

Most programs allow for the user to create a one-time or temporary part. As is often the case, these are odd-ball items you’re trying to address. If the receiving program doesn’t know what that temporary part is, chances are good that it’ll go wrong. It’s absolutely critical that you “check the chute” to make sure that everything in the import/export stream made it from one side to the other unaltered.

Be advised that some patched programs will doggedly resist any efforts to alter the audit. Say you imported the job then noticed you were short one item. It’s an easy fix to add one more on the estimating program. If the takeoff program quantities differ from the estimating program quantities, some systems will badger you senseless.

This is particularly infuriating when a project comes in over-budget prompting the design team to “revise” their plans before demanding immediate pricing revisions. It might be perfectly obvious that you’re deleting this and adding that. Getting the system to quickly make those changes can be a needlessly difficult task. Two scope changes can result in upwards of fifteen separate operations just to stop the error messages from popping up.

In fact, it’s often easier to just create a “new job” that’s nothing more than the addition and subtraction of various line items. Be advised that it’s far from ideal to hand over an estimate with a stack of rag-tag modifications attached. Many Project Managers will insist on a “clean” estimate that reflects what they’re under contract to build. So “save time” at your own risk!

Alternates

“Do this instead of that” sounds pretty simple but most estimating software is woefully equipped to get this right the first time. QTO systems range from pretty good to outright hostile to alternate pricing. Much of how it will behave hinges on how the data is compiled. Repeated conditions get tallied, that makes sense since it’d be annoying to have fifty measurements of the same carpet type rather than a total for all of it. If the system can’t/won’t delegate between base bid and alternate for each measurement, the alternate get’s thrown in with the base bid tally skewing everything.

Multiples

Apartments and hotels often have repetitious floor plans where the designer will only detail a single example of each repeated plan. Some QTO systems are built without the capacity to define everything on a given plan as a multiple. I’ve struggled through 250 room nursing home takeoffs that took heroic efforts to work around this shortcoming. If you’re bidding multifamily work, don’t buy these programs. Most salesman are spectacularly unaware of how useless a program becomes when it can’t do basic math functions like these. In case you’re wondering, some estimating programs can multiply imported items. So while it is technically possible to calculate multiples, you’re going to be selecting these items down out of a long list of similar entries. Once a change is made it can be very difficult to be sure you’ve done it right. I would strenuously advise against this practice because it’s very slow and error prone.

Pictured: a slow and error prone approach

Overlays

Overlays allow two plan pages to be displayed at the same time. Most commonly, overlays are used to compare different versions of the same plan as with Addenda or ASI’s. Comparative overlays generally color new blue, and existing red. Anything that perfectly aligns is purple indicating no change. It’s possible to catch Design teams that don’t/won’t bubble changes to their revisions using overlays. That being said, it’s an imperfect solution. If the plan is moved within the space on the page, it’s no longer possible to align everything at the same time. Overlays work one page at a time, so addenda that replace every sheet means you’ll be overlaying every sheet individually. The old-school addenda method of putting changes on “sketches” formatted to a 8-1/2″ x11″ page so they could be faxed is a constant source of misery. Overlaying multiple sheets, with different orientations, and scales is barely possible with some systems. In fact some programs only allow a single overlay at a time. Comparing more than one set of changes is a multistage process.

Subtle changes to scale, alignment, and orientation all require constant fiddling while staring at a blurry purple screen. Design teams with several addenda, will often remove earlier bubbling which adds to the discrepancies you must sort through in the overlay. Text changes within schedules will be illegible in the overlay. Sadly this advance in technology has been greeted with enthusiasm by irresponsible design teams who see it as an opportunity to avoid writing a narrative of their changes. Often these teams simply replace the entire plan set regardless of whether changes were made to every sheet. Lacking bubbling, the estimators are obligated to long hours of eye strain trying to figure out what happened. General Contractors can and should demand design-team narratives of changes to uphold professional integrity.

Updates, upgrades, marketing and mischief

I once had a QTO program that after some intensive setup was working really, really well. After a year or so, the program was sold to a different company who announced that a new and improved version was coming out. Emails listing all the new features were very exciting. Compatibility with popular tablets, phones, and programs were touted and many promises to smoother functioning were made.

Long story short, the upgrades caused problems which were patched, causing further problems eventually reaching a point where about 10% of the plan sets I had to bid on wouldn’t import into the program. Their software developer told me directly that it was a marketing decision to hold off on providing the desperately needed fixes until they’d worked out their newest upgrade which made them compatible with Apple computers for the first time.

To those marketing folks, there’s no “selling point” to software that just works. The priority was having some new feature to advertise. Everything was about upgrade launch dates followed by inevitable patches to fix whatever was broken. If there weren’t enough people clamoring for help with a problem, it didn’t get fixed.

They would consider this a lifetime parking upgrade

I still receive about five emails a year from them informing me that they’ve decided to put another one of my suggestions into development for future upgrades! Sadly the “make it work as advertised” suggestion remains unaccounted for. It’s been years since I worked with that system, it had great potential and terrible ownership.

Training

Just about every legitimate estimating software supplier will include free training and a free trial of their program. In my experience, the free trial was a limited “viewer” version of the real program. In other words, it wasn’t possible to actually complete an estimate but you could see a bunch of unresponsive icons and menu screens. Several firms create a “user database” of video tutorials that provide instruction on how the various parts work. The video’s are great provided you do things EXACTLY as depicted. Few of these tutorials spend much time explaining why you’d check a certain setting. Misleading option names, and unfamiliar layout leaves a user desperate to understand why it won’t just do what it’s told.

The salesperson will recommend you spend some time watching the video tutorials and puttering around with the software before your training session. In my experience, the “trainer” will get on the phone with you, link up to your computer and conduct a “mock estimate” that’s literally identical to the training videos. I found myself asking more advanced questions of the trainer, and they never knew the answer.

Tech Support

It can be very frustrating to wait on hold knowing you’re just getting further behind schedule. The key is to understand that tech support is WAY more qualified to answer user questions than the sales and marketing team. Once they’ve solved your main problem, take the opportunity to ask questions to learn more about the program. These folks teach really well because they can usually log onto your machine and literally point you in the right direction.

If you’re learning the system from a co-worker, be advised that typically they’ve worked out their way that works. Asking questions about un-used options may frustrate them.Lots of people have a “need to know” policy about all those options. If they don’t use them, they figure they don’t need to know what they control! I encourage you to be curious and thorough. Software may provide multiple paths to the same solution. Understanding how they all work allows you to find the most effective way.

Workarounds

Its sometimes possible to work around a programs shortcomings. For example if you’re using a Project Management program that doesn’t have normal text editing features, you can copy and paste text out of a word processing program into the Project Management text insertion windows.

Bill of Materials (BOM) are common requests and a complete nightmare to output with some QTO systems. However nearly all QTO systems feature an “Export to spreadsheet” function that you can then sort, cull, and print. Whenever you’re trying to “check the chute” to verify that the QTO program exported everything into the estimating program, it’s really handy to have a list of what was supposed to export to check against. Estimating programs will generate reports which consolidate the data making it difficult to see what might be missing. For example if your estimate program displays 1,000 feet of pipe, but your exported list tallies to 1,020 feet, you’d know to look through your export list looking for a 20 foot long measurement. Chances are excellent that will be the one that didn’t import properly. Plus most spreadsheet programs will “find” a keyword or number with a search function so you can quickly get to the entry that’s in question.

Tips

Check the scale. I’ve won at least two major projects because the scale was not correct on the drawing. Commercial doorways are 3′-0″ wide. Parking stalls are 9′-0″ x 18′-0″. If the plan scales different, you know there’s reason to be suspicious. Be advised that any plan developed by an Architects consultant is probably drawn on the Architect’s background drawings. So if the Mechanical floor plan is labeled at a different scale than the Architects floor plan of the same space, chances are good that one of them is wrong. Most commercial projects utilize similar scales for their plans. Architectural floor plans are often 1/8″ = 1 foot or 1/4″ = 1 foot.

Scales like 3/32″ = 1 foot and 3/16″ = 1 foot are really close to the “normal” scales, be very careful. Many QTO programs will crash if you try to change the scale AFTER doing a lot of measurements. Also check that your scale is correct vertically and horizontally. I caught on to a local printer who was mistakenly creating files that had different vertical and horizontal scales!

Define any alternate early on. It’s generally much less difficult to control where things end up when you define them at the start. Often alternates defined with the job can be imported/exported between programs much easier at the start than later on.

Import the alternates last. Estimating programs have an audit display showing all the imported data. Most will default into order of entry. By leaving the alternates to last, you can jump to the bottom of what can be a REALLY long list. Having everything for an alternate in the same place reduces the confusion and searching when the deadline is looming.

QTO programs will display your takeoffs on the plans. “If it’s colored, it’s counted” is their credo. Depending on display settings; the icons, line weights, and numeric references, can obscure a great deal of the plan. It’s entirely possible to take off a wall section on a plan view and lose sight of a window you should have counted. Unless you provide a means to “turn off” the wall QTO, you won’t notice when you’re missing something. Conversely, if you don’t have a means to only display windows, it’s harder to notice one missing. Some programs have check-boxes next to QTO items allowing users to turn them on or off. Other programs require QTO items to be categorized in “layers” which can be turned on or off. Going along counting a repetitive item it’s easy to miss just one. If those items are the only ones lit, it’s much easier to verify by symmetry, function, and overall layout.

It takes a deft touch…

Auto count, the incompetent tool.

QTO program salesman love to tout their cutting edge auto-counting tool. It’s supposed to reduce the drudgery and knock out QTO’s like clockwork. They are uniformly terrible in my experience. If a salesman offers to demonstrate this tool, make sure they use your plans. Real project plans are much harder for these tools.

Copy and paste the indispensable option.

A much bigger deal is being able to copy and paste a slew of takeoffs. Architects love symmetry so lots of elements in their designs are copy’s or mirror images. Not every system CAN copy and paste. Being able to rotate, invert, or flip a copy can finish a takeoff in a fraction of the time. It’s a really big deal that nobody talks about.

Patterned workflow

If you’re using a separate QTO and Estimating program, you’ll benefit from a patterned workflow. Estimating programs will have a unique input format for each entry. Structure your QTO output to match the estimating programs format. It’s much less work to have the data in the order it’s asked for. Also, if your estimating system has separate menu’s for different assemblies, divide your QTO output accordingly. You might have noticed that I’m writing “QTO output” rather than QTO program. Exporting to a spreadsheet allows you to change the order of the items by sorting.

If you pay attention to how your QTO program exports, you might find that doing your takeoffs in a particular order helps smooth out the works. Smooth is fast, so focus on reliable techniques to improve your workflow. QTO programs will sometimes allow the user to select or define divisions, breakdowns, etc. You might find that you can sort the exported spreadsheet by these terms thereby reducing your labor to put everything in order.

QTO and estimating programs can be a great asset in the modern bid market. I’ve been able to consistently increase the quantity and quality of my bids year after year. I owe much of my increased productivity to QTO programs. These programs will NOT make you a better estimator, nor will they prevent you from making mistakes. Like everything in estimating, it’s about controlling risk. Automatic operations seek to avoid “human error” and to a great extent they do. Programs are only as good as their code. Eventually the system will do something unpredictable. Never forget that it’s your bid and your company that must accept the risk. Control the risk by checking on your programs frequently.

For more articles like this click here

© Anton Takken 2015 all rights reserved